Specific connotations, advantages and disadvantages, and considerations of exporting complete machines and parts:

I. Whole machine exports

1. Specific content

A complete export is the direct export of a fully assembled product to a target market, such as the export of complete mechanical equipment, household appliances or automobiles.

2. Advantages and disadvantages analysis

Advantages:

- High added value: Complete products usually have larger profit margins;

- Brand Effect: Contribute to the establishment of an international brand image for the enterprise;

- After-sales service: It can directly control the after-sales process and enhance customer satisfaction.

Disadvantages:

- Higher tariffs: Higher tariff rates are usually applied to whole products;

- High logistics costs: Large, heavy and expensive to transport;

- Complex certification: Need to meet the whole machine certification requirements of the target market (e.g. CE, FCC).

3. Issues that need attention

- Certification Compliance: Ensure that the whole product passes the mandatory certification of the target market (e.g. EU CE certification, US FCC certification);

- Packaging and Shipping: Ensure that the whole product passes the mandatory certification of the target market (e.g. EU CE certification, US FCC certification);

- After-sales service: Establish a localized after-sales team or agent network to respond to customer needs in a timely manner.

II. Exports of spare parts

1. Specific content

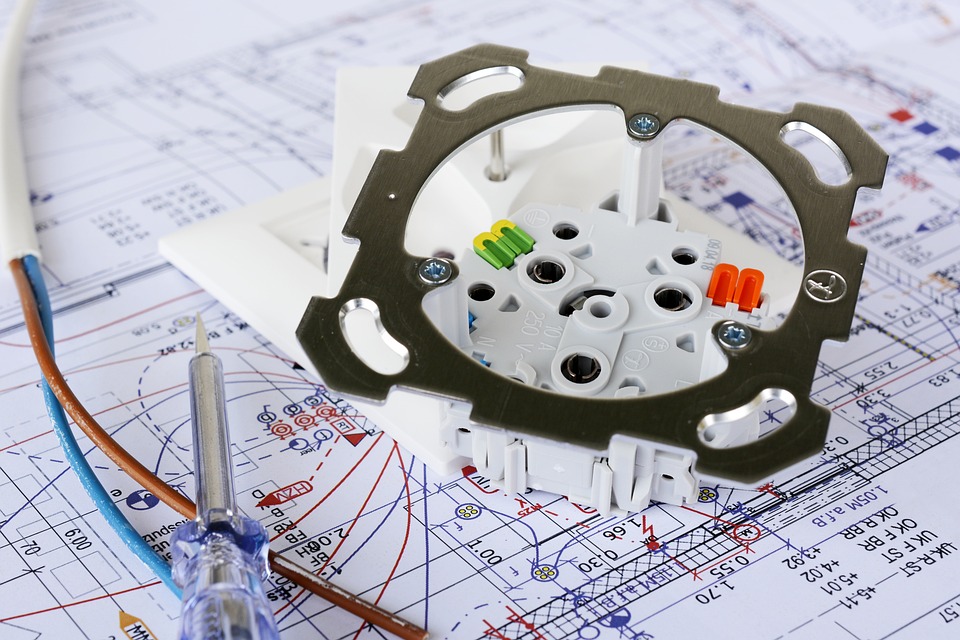

Exports of spare parts refer to the export of components of a product to a target market, such as the export of engine parts, electronic components or mechanical parts.

2. Advantages and disadvantages analysis

Advantages:

- Lower tariffs: Parts are usually subject to lower tariff rates;

- Flexible logistics: Small size, light weight and low transportation cost;

- Simplified authentication: Some parts do not need to be certified in their entirety, resulting in lower compliance costs.

Disadvantages:

- Low added value: Smaller profit margins on parts products;

- Strong dependence: Need to work closely with OEMs in target markets;

- Weak brand effect: It is difficult to build a direct end-to-end brand image.

3. Issues that need attention

- Technical specifications match: Ensure that parts meet the technical requirements of the OEMs in the target market;

- Supply Chain Management: Establishing long-term cooperative relationships with machine manufacturers to ensure order stability;

- Protection of intellectual property: Avoid infringement of patents or trademarks in the target market.

III. Comparison of exports of complete machines and exports of spare parts

| sports event | Whole machine exports | Exports of spare parts |

|---|---|---|

| Added Value | high | Low |

| The Customs | Higher | Lower |

| Logistics costs | high | Low |

| Certification requirements | Complex (whole machine certification) | Simplified (some parts do not require certification) |

| Brand Effect | powerful | weak |

| After-sales service | Localization team required | Dependence on machine manufacturers |

IV. Selection Strategies and Recommendations

Choose by target market:

- developed country(e.g., Europe and the United States): Prioritize the export of whole machines and leverage brand premiums;

- Emerging Markets(e.g. South-East Asia): Exports of spare parts could be considered to lower barriers to entry.

Choose according to enterprise capabilities:

- Strong technology and sufficient funds:: Whole machine exports and the establishment of brand barriers;

- Small scale and limited resources: Parts export, specializing in niche areas.

Blending Mode:

Setting up assembly plants in target markets, exporting parts and assembling them locally, balancing tariff optimization and brand building.

Conclusion

Explore Chinas export models: Complete machinery vs parts. Key factors: compliance, supply chain, branding. Optimize your global strategy now.

Follow the customer service WeChat account.

Follow the customer service WeChat account.